Due to urban growth and the saturation that it originates, urban transport market is expanding rapidly throughout the world, demanding new requirements that request specific products; ArcelorMittal offers a wide portfolio of railway products for Tram and Light Rail Systems produced at our world-class manufacturing plants. Our process complies with most demanding European requirements according to EN 14811.

Low carbon vanadium grades for increased service life

ArcelorMittal offers a complete range of Low Carbon Vanadium (LCV) grades for grooved rails which provide better performance and increased service life for Light Rail Transit operators.

At ArcelorMittal, we are actively involved in designing new rail-based solutions that meet the needs and requirements of light rail transit (LRT) operators with the support of our ArcelorMittal Global R&D rail unit. Thanks to pilot plants and prototyping facilities, new products and rail mill processes can be developed, as well as monitor on-track real performance, wear behavior to fatigue, and weldability.

Low Carbon Vanadium (LCV) for better performance, why?

- Able to perform gauge corner restoration.

- Easy maintenance.

- Welding according EN 16771.

- Increased wear resistance.

- Increased fracture toughness.

- Low brittleness.

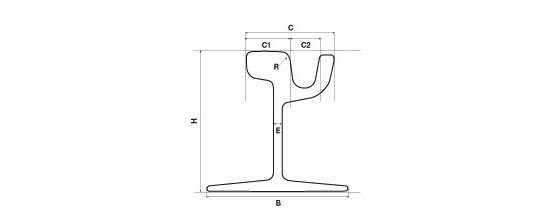

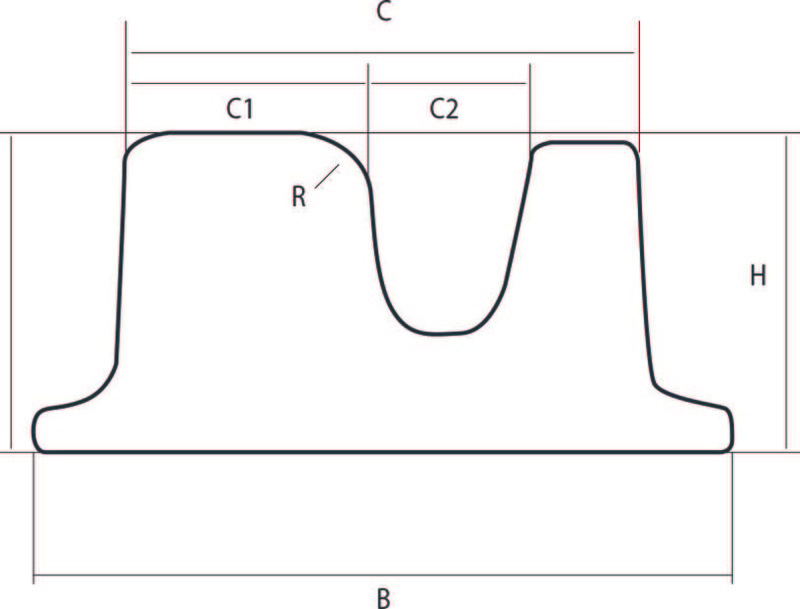

Grooved

Profile Standard Dimensions mm Tolerance Weight H B C C1 C2 E R Group kg/m 51R1 (Ri52) EN 14811 130,00 150,00 113,00 55,83 42,35 12 13/80/300 G or R 51,37 53R1 (Ri53) EN 14811 130,00 150,00 113,00 55,83 36,34 12 13/80/300 G or R 52,98 54G1/54R1 (41GPU) EN 14811 152,50 141,50 116,82 56,16 41,09 13 13/60/200 G or R 54,26 54G2 (Ri54G2) EN 14811 152,50 141,50 116,80 55,91 41,55 13 13/80/200 G 54,55 54G4 (41GPi) EN 14811 152,52 141,50 116,82 56,22 40,83 13 13/60/200 G or R 50,09 55G3 (41GP13) EN 14811 152,50 141,50 116,82 55,61 40,18 13 13/225 G or R 55,27 55R1 (Ri55NK) EN 14811 150,00 150,00 113,00 56,00 36,00 12 13/80/300 R 55,45 57R1 (Ph37) EN 14811 182,00 150,00 127,00 51,92 60,46 11 9/210 G or R 56,54 59R1 (Ri59N) EN 14811 180,00 180,00 113,00 56,00 42,00 12 10/225 G or R 58,97 59R2 (Ri59N) EN 14811 180,00 180,00 113,00 55,80 42,50 12 13/80/300 G or R 58,14 60R1 (Ri60) EN 14811 180,00 180,00 113,00 55,00 36,00 12 10/225 G or R 60,59 60R2 (Ri60N) EN 14811 180,00 180,00 113,00 55,83 36,35 12 13/80/300 G or R 59,75 62R1c (NP4aM) EN 14811 180,00 180,00 116,00 56,03 34,44 12 10/25 G or R 62,37 62R2 (Np4aS) EN 14811 180,00 180,00 116,00 56,86 36,98 12 13/80/300 G or R 61,91 Grooved Rail: bar length up to 18 meters / Chemical composition as per European standards. Block Rail

Profile Standard Dimensions mm Tolerance Weight H B C C1 C2 R Group kg/m 53K2 (MSzTS52) EN 14811 70,00 156,00 116,00 56,00 45,00 10/225 – 53,34 57K2 (LK1) EN 14811 72,00 156,00 115,00 56,00 36,00 13/80/300 – 57,68 58K2 (112T) EN 14811 72,00 156,00 120,00 56,20 41,50 13/60/200 – 58,29 Block Rail: bar length: up to 18 meters. Vignole

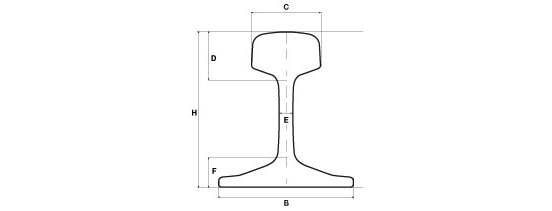

Profile Standard Dimensions mm Section S Weight H B C D E F cm² kg/m 49E1(S49) EN 13674-1 149,00 125,00 67,00 51,50 14,00 27,50 62,92 49,39 50E6(U50) EN 13674-1 153,00 140,00 65,00 49,00 15,50 28,00 64,84 50,90 54E1(UIC54) EN 13674-1 159,00 140,00 70,00 49,40 16,00 30,20 69,77 54,77 Vignole Rail: bar length from 18 to 90 meters Chemical composition as per UIC, Euronorm and Arema standards.

Product Contact

Frederic GOUJON | Product Manager Crane, Grooved and Light rails

ArcelorMittal Europe – Long Products – Rails & Special Sections

66, rue de Luxembourg

L-4221 Esch-sur-Alzette | G.D of Luxembourg

rails.specialsections@arcelormittal.com